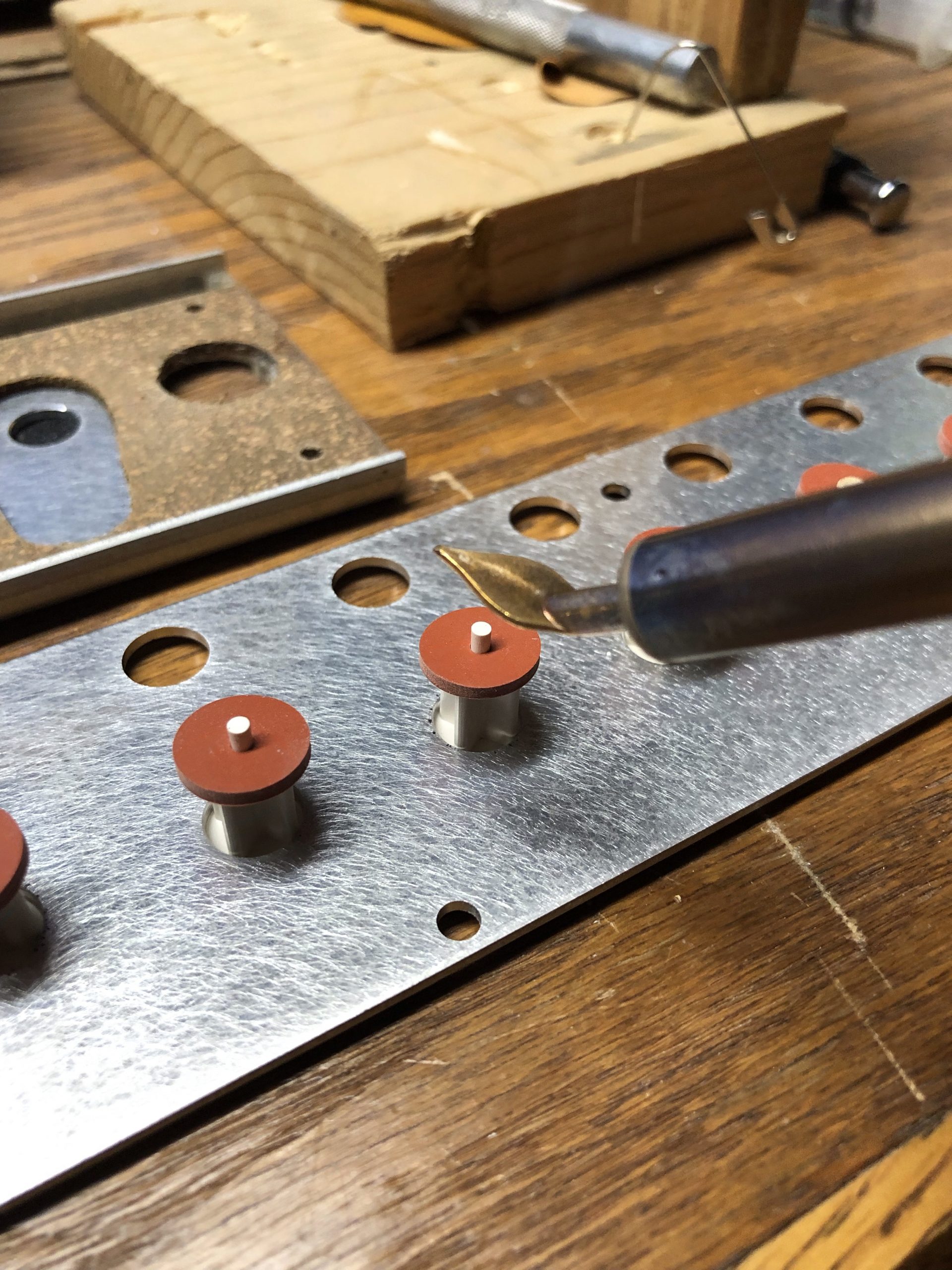

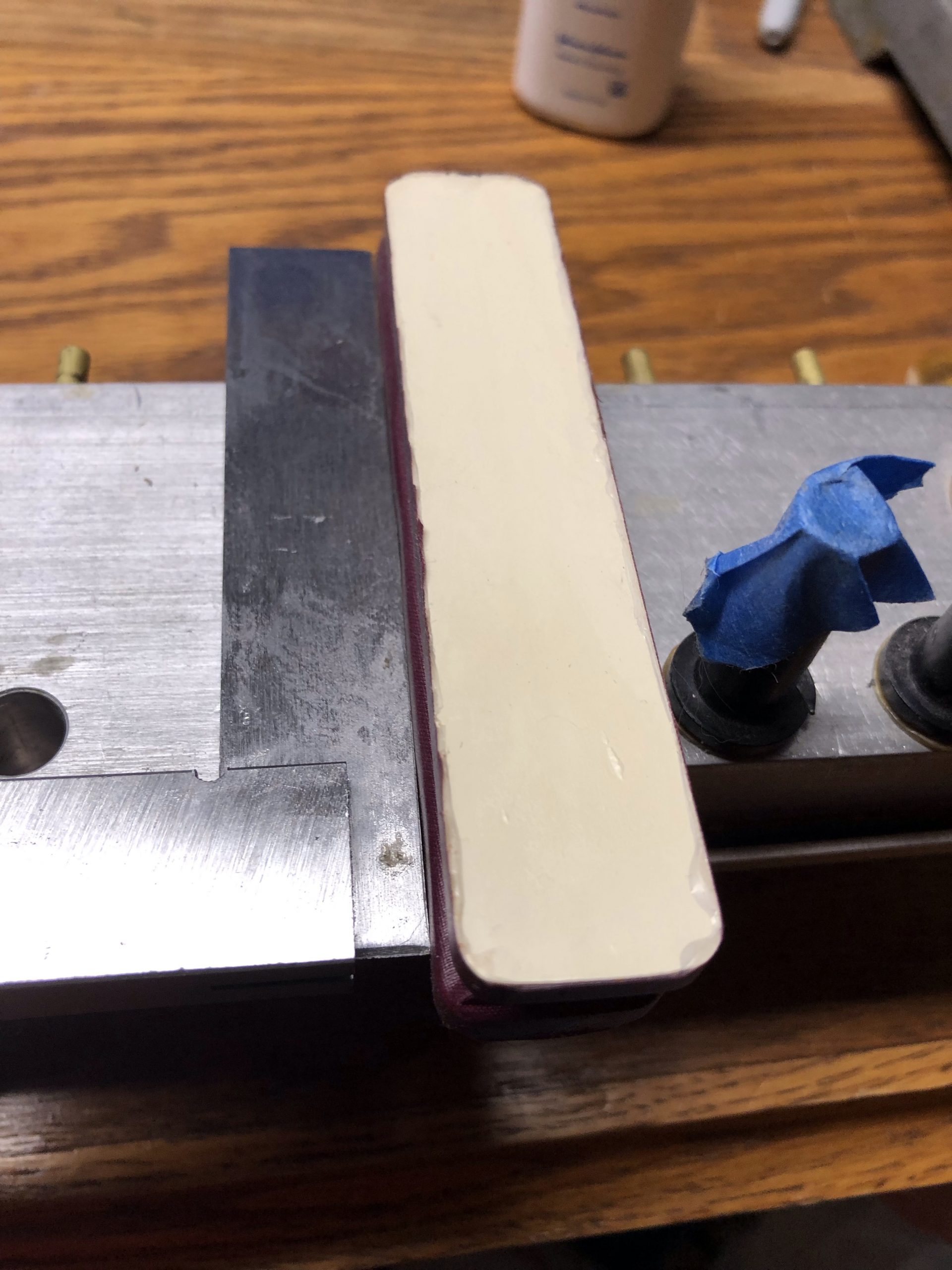

This project required complete disassembly and replacement of internal parts. Originally built in the mid – 1980’s, materials used at the time were “state of the art” plastics. Over time, degradation of the materials dictated that any service should include replacing these materials. The brown disks are actual leather, specially made for this purpose and traditional installation processes were used – rubber cement sealing, talc lubrication, etc. The striker pneumatics – the long, narrow rectangular objects – are what plays the note and while still plastic are replacements for the originals. They came with two halves and new cloth had to be cut and glued to them. There are two rows to the full assembly, so everything was basically done twice!

Leave a Reply